Merken

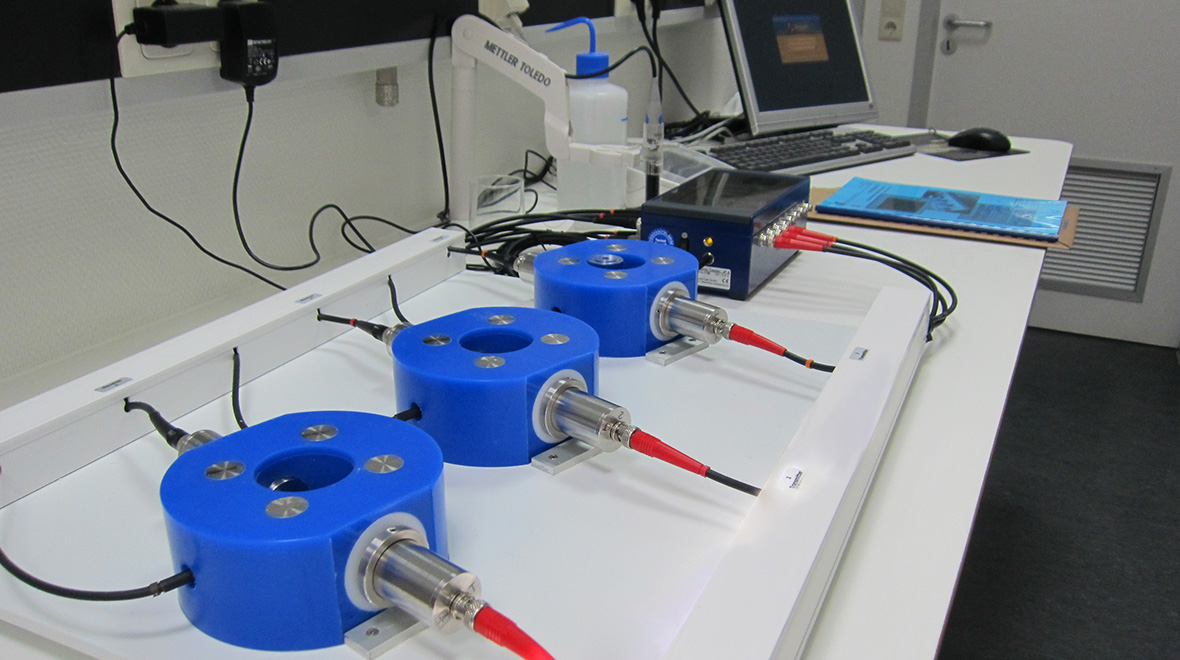

IP-8 Ultrasonic Measuring System

for Precise Measurement of Setting Processes

High-precision 8-channel ultrasonic measuring system – for precise measurement of setting processes, strength development and changes in the consistence. Suitable for organic and inorganic building products, binders and adhesives as well as the food industry within the fields of development, production, research and teaching.

IP-8 Measuring System in use

Analysis of Ultrasonic Speed

IP-8 Measuring System – Video

Main Features

- High-precision measuring system (resolution 0.05 μs)

- 8 independently controllable channels

- Intuitive software for control and evaluation

- Simple and easy to use in everyday lab work

- Suitable for industrial applications

- Optional PLC control and integration in production lines

Applications

- All materials with a setting process (e.g. cement, mortar, gypsum, concrete)

- Heat insulation and render systems

- Construction chemicals, additives

- Gypsum products and adhesives

- Refractories, castables

- Food industry

Advantages of Ultrasonic Measurements

- Precise display of the setting process

- Immediately visible results at different formulations

- Exact reproducibility of measurement results

- Identification of deviations at an early stage

- Strength development from initial mix to 28-day strength in a single measurement

- Easy handling and operation makes it perfect for laboratory use

- Easy demoulding and refi lling of the measuring moulds

- Ideally suited for quality assurance and production

- Up to 30% reductions in development time and cost

- Software available in various languages

ip-8-four-tabs-_en

transparent

600

#cccccc

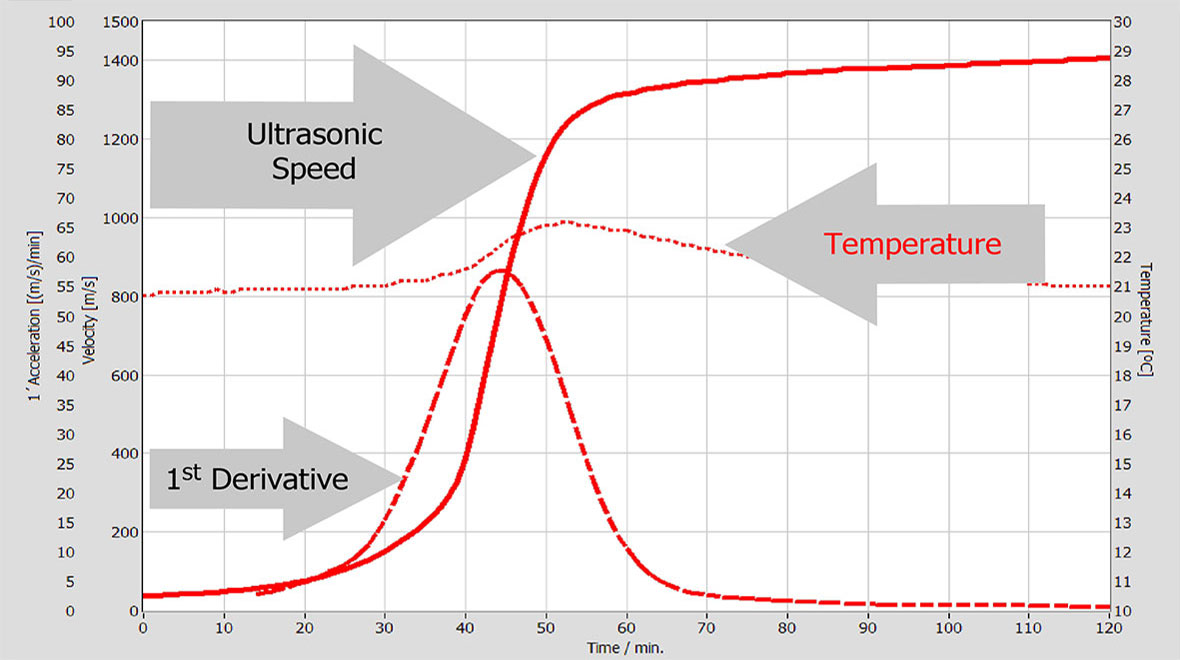

UltraTestLab© – Control and Evaluation Software

- Intuitive operating concept with a clearly arranged user interface

- Measurement duration: 15 minutes – 365 days

- Measurement interval: 1 second – 60 minutes

- During measurement simultaneously visible:

- 1. Speed in m/s or runtime in μs

- 2. Curve derivation (acceleration) and curvature

- 3. Temperature inside the sample (-20 ... +125 °C)

- 4. Shrinkage/swelling by connection of “shrinkage grooves” (optional)

- Comparable against reference measurements

- Reproduction of characteristic points such as initial set and fi nal set with graphic markers

- Permissible deviations defi nable with envelopes

- Evaluation, Excel export and printouts possible during measurement

- Automatic logging of all measurements

- Dynamic e-modulus calculation and display

- Option: external temperature measurement by thermocouples (-40 ... 1820 °C)

- Option: measurement of shrinkage/swelling by connection of ”shrinkage grooves”

Add Ons

- ASEM Shrinkage & Expansion Measuring System (Flyer): Simultaneous measurement of setting processes as well as shrinkage & expansion

- ASEM Shrinkage & Expansion Measuring System (Video): Simultaneous measurement of setting processes as well as shrinkage & expansion

- Logistic Fitting: Software module for breaking down ultrasonic curves into several logistical sub-functions and their derivatives

- Compressive Strength: Software-Module to determine the compressive strength from sound velocity by correlation

Test Service

Should you be interested in a presentation with test measurements on your products, we would be pleased to arrange an appointment. Alternatively you can send us up to 3 product samples for a test measurement. The results will be e-mailed to you as a PDF or Excel file within a few days.

Contact: +49 (0)4202 955 1390

Email: mail(at)ultratest.de

IP-8 Messsystem

Mortar, plaster, thermal composite system

Construction chemicals, additives, waterprofing

Refractories, castables

Facades, floor, roofing systems, drywall

Universities, research, teaching

Cement, concrete, construction materials

3D Printing